What we learned from the MOD X / BE-ST Scotland Exchange 2025

MOD X / BE-ST Scotland Exchange 2025 Group (courtesy of MOD X)

In early November we went on a 1-week exchange organized by MOD X and Built Environment - Smarter Transformation (BE-ST), Scotland’s national innovation center for construction and the built environment. It is worth recognizing some key insights from our trip that will inform our work in Baltimore:

MOD X and BE-ST planned and coordinated a highly informative and inspiring trip; their collaboration demonstrated how innovation thrives BEST (pun intended) when ideas are generously shared at a global level. If Baltimore is to advance our industrialized construction ecosystem, we need to tap into this global exchange of ideas. Baltimore needs a physical place for an industrialized construction innovation center that pulls together government, industry, education and community/non-profit stakeholders.

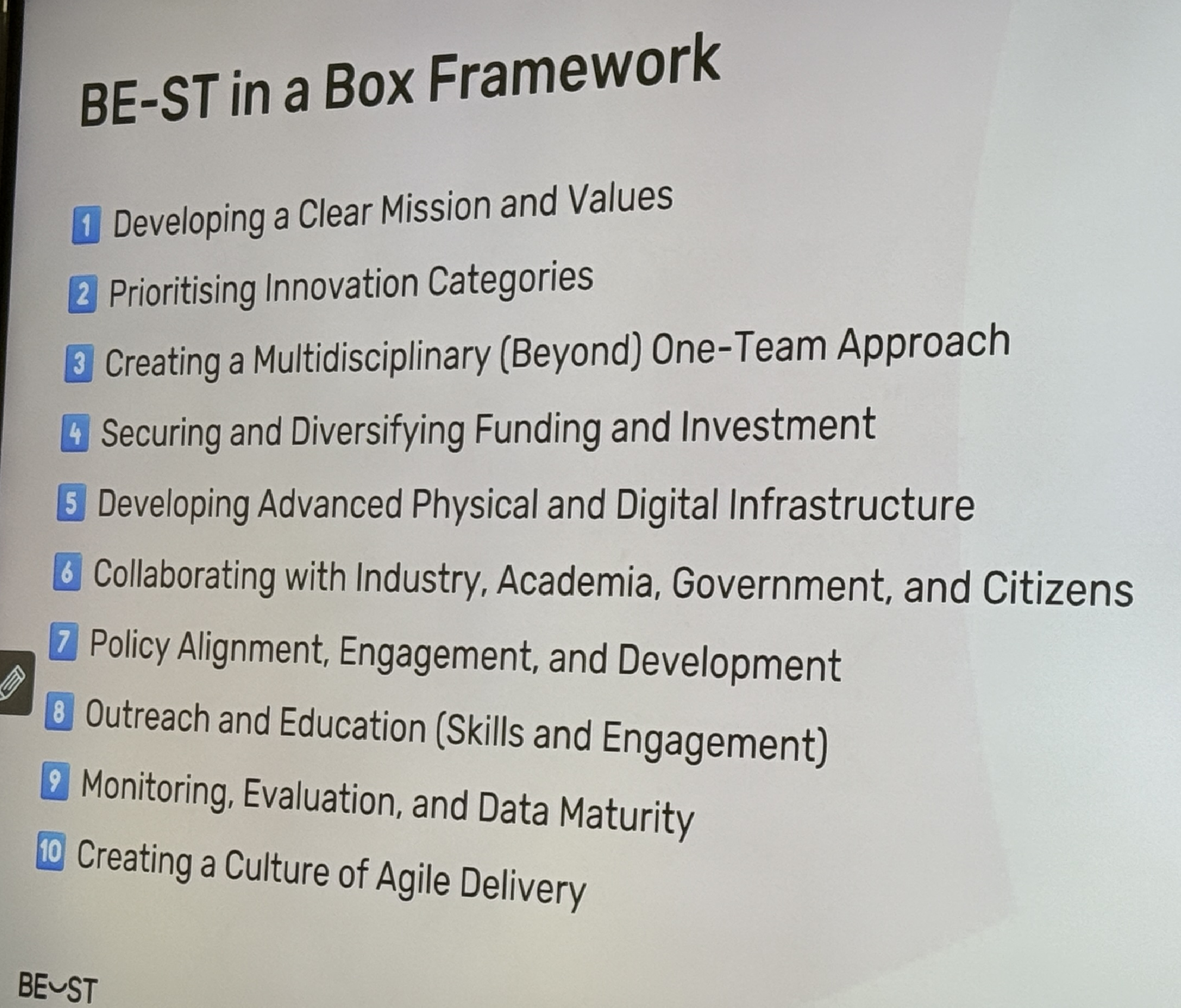

Baltimore does not need to reinvent the wheel when it comes to developing a construction innovation hub. BE-ST gladly shares how their innovation hub model can be replicated through their BE-ST in a BOX Framework (thank you BE-ST).

We were joined on the exchange by people from Sweden, Ireland, the UK (Scotland and England) and the U.S. Shockingly, we learned that we are all grappling with similar problems: the lack of affordable housing combined with construction labor shortages. And the retrofitting of existing buildings is also a common concern. Again, tapping into a global exchange of ideas will ensure that even regions who are catching up on solving these common problems (such as the Baltimore region!) do not need to start from square one.

While a global amassing of ideas is essential for any one region to thrive, there must also be a parallel local amassing in the form of 1) aggregated localized/contextualized R&D with the region’s quadruple helix of stakeholders and 2) aggregated demand for industrialized products through innovative procurement vehicles specifying offsite construction.

All of the countries with which we interacted are focused on wood construction due to its carbon capture, renewability, and affordability. That’s not to say they were ignoring the advancement of other materials but wood certainly holds much promise for these countries. They also appreciated that it can be a “homegrown” solution that will lead to less reliability on imports. It’s time for Baltimore to develop robust wood product supply chains!

Robots are optional! Industrialized offsite construction requires a departure from how we traditionally build things but the level to which a factory is automated varies widely. On our trip we saw both highly automated facilities and those that rely predominately on human labor - people working inside on tables - with some tasks augmented by machines. The take away for Baltimore is that a huge upfront investment in machines is not needed to get to work! But robots are cool.

BE-ST in a Box Framework